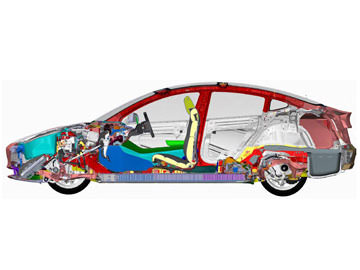

The OXI way

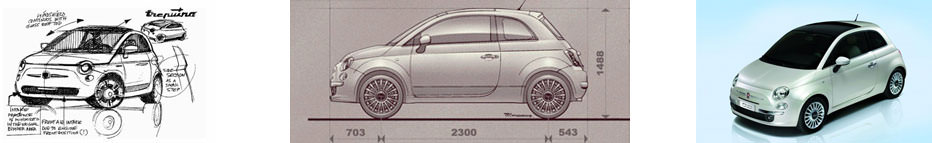

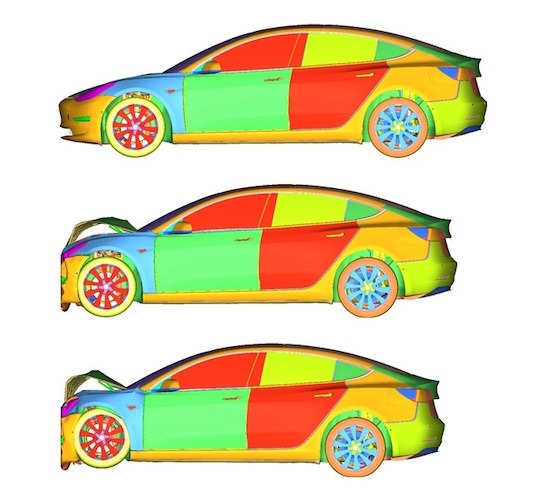

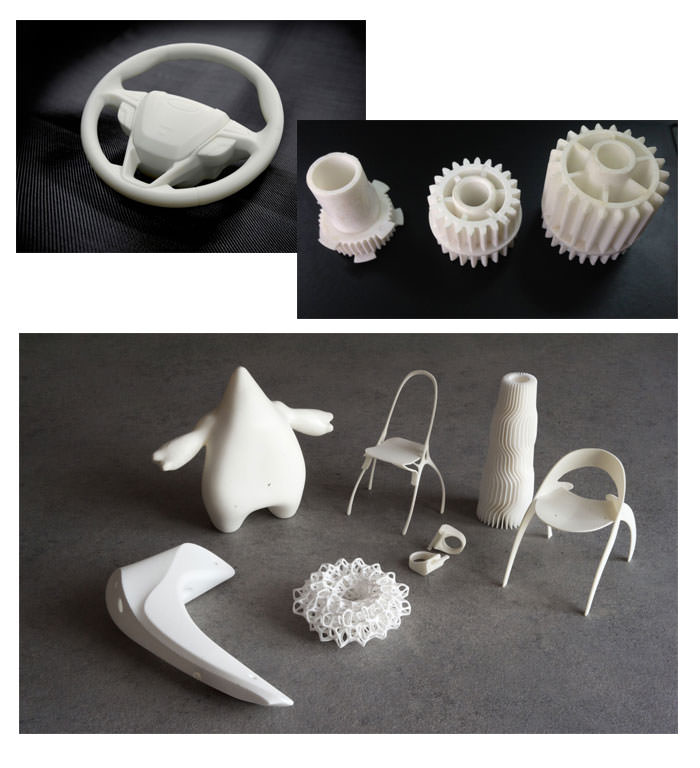

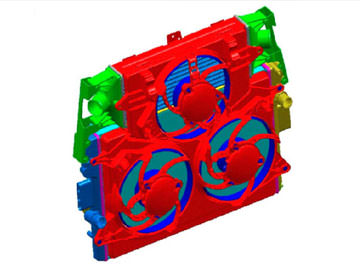

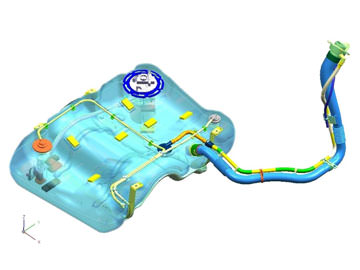

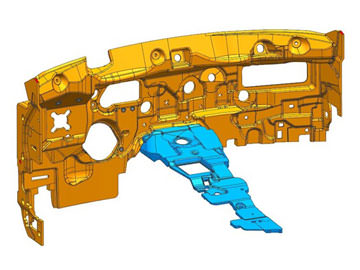

The specific know-how gained in the field of plastic and mechanical components, in terms of product and process engineering, makes it possible to fully integrate OXI with the different company functions of the customer at different stages of development.